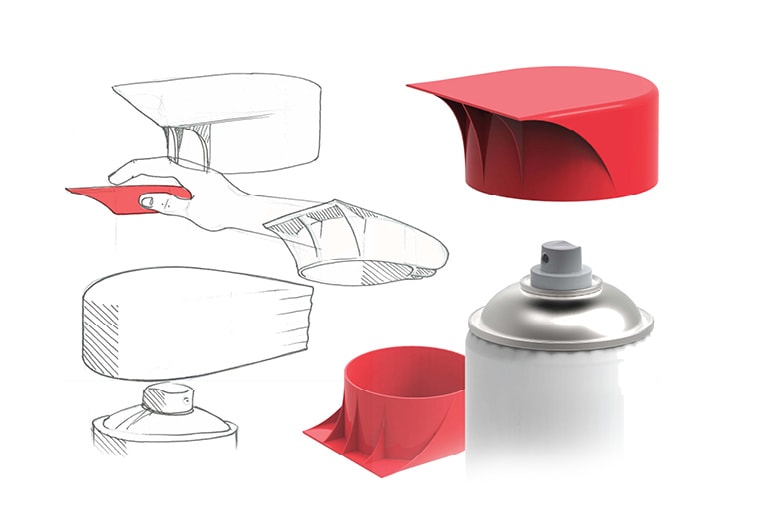

Unipart ice cap:

Easy ice scraping

The brief

Unipart invited a number of agencies to present how they would invigorate the Unipart automotive brand with innovative solutions and deliver that in a fresher brand identity. We were fortunate to be selected and we went about looking at the problems customers have using “car care” products. We delivered dozens of innovative concepts and the de-icer was chosen as one of the first to bring to market.

The bang

The de-icer can has to have a cap on it. Making that cap into an ice scraper has been done before, however those designs had the scraper pointing up in the air. It is easier to mould that way. But, our solution had a scraper protrude from the side. It was a lot more user friendly and in research it looked more appealing on shelf, assisting sales. The problem our solution caused though was it is hard to stack and ship and hard to put on in production.

The result

To overcome the logistic issues, we changed the geometry and added recesses, which allowed the cans not only to nest side by side, but also vertically. A cap can support the base of an on top of it. Along with the new branding we did across their range , this new form really stood out on line and on shelf, and overcame any logistical and manufacturing issues. It proved to us that innovation has to be chased right through production and on the shelf. Having an idea is easy, Delivering it was a real challenge.

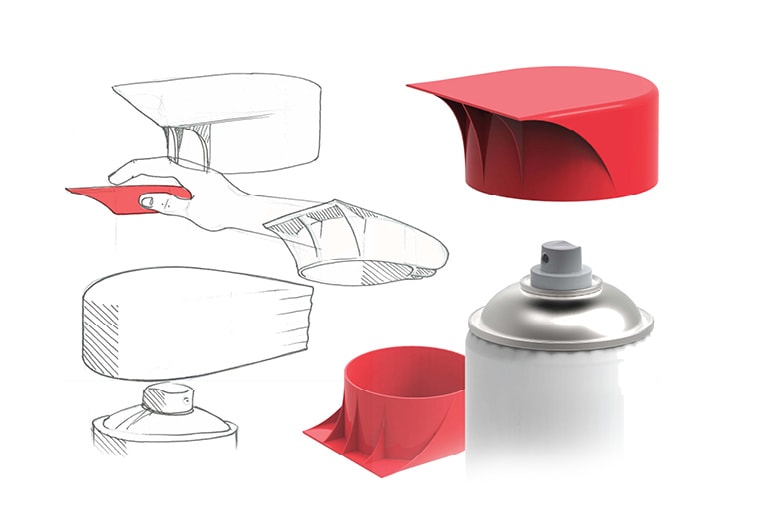

Unipart ice cap:

Easy ice scraping

The brief

Unipart invited a number of agencies to present how they would invigorate the Unipart automotive brand with innovative solutions and deliver that in a fresher brand identity. We were fortunate to be selected and we went about looking at the problems customers have using “car care” products. We delivered dozens of innovative concepts and the de-icer was chosen as one of the first to bring to market.

The bang

The de-icer can has to have a cap on it. Making that cap into an ice scraper has been done before, however those designs had the scraper pointing up in the air. It is easier to mould that way. But, our solution had a scraper protrude from the side. It was a lot more user friendly and in research it looked more appealing on shelf, assisting sales. The problem our solution caused though was it is hard to stack and ship and hard to put on in production.

The result

To overcome the logistic issues, we changed the geometry and added recesses, which allowed the cans not only to nest side by side, but also vertically. A cap can support the base of an on top of it. Along with the new branding we did across their range , this new form really stood out on line and on shelf, and overcame any logistical and manufacturing issues. It proved to us that innovation has to be chased right through production and on the shelf. Having an idea is easy, Delivering it was a real challenge.

Unipart ice cap:

Easy ice scraping

The brief

Unipart invited a number of agencies to present how they would invigorate the Unipart automotive brand with innovative solutions and deliver that in a fresher brand identity. We were fortunate to be selected and we went about looking at the problems customers have using “car care” products. We delivered dozens of innovative concepts and the de-icer was chosen as one of the first to bring to market.

The bang

The de-icer can has to have a cap on it. Making that cap into an ice scraper has been done before, however those designs had the scraper pointing up in the air. It is easier to mould that way. But, our solution had a scraper protrude from the side. It was a lot more user friendly and in research it looked more appealing on shelf, assisting sales. The problem our solution caused though was it is hard to stack and ship and hard to put on in production.

The result

To overcome the logistic issues, we changed the geometry and added recesses, which allowed the cans not only to nest side by side, but also vertically. A cap can support the base of an on top of it. Along with the new branding we did across their range , this new form really stood out on line and on shelf, and overcame any logistical and manufacturing issues. It proved to us that innovation has to be chased right through production and on the shelf. Having an idea is easy, Delivering it was a real challenge.