ProCut

Faster Pipe Cutting

The brief

The relationship between Drainfast and Bang Creations continues to develop. The next challenge they shared with us, one that many of their clients have. How could the pipe cutting process for underground drainage pipes be improved? Specifically they wanted to improve the cut and chamfer process on 110mm diameter underground drainage pipes. The approaches commonly used on site are either slow or inherently dangerous, so much so that many sites prohibit cutting pipes with grinders. The developed pipe cutting tool would accompany the SiteStak, and also work well as a standalone tool. Bang previously developed a low-cost option for a cutting guide for their SiteStak’s, but Drainfast wanted to take this success further.

The bang

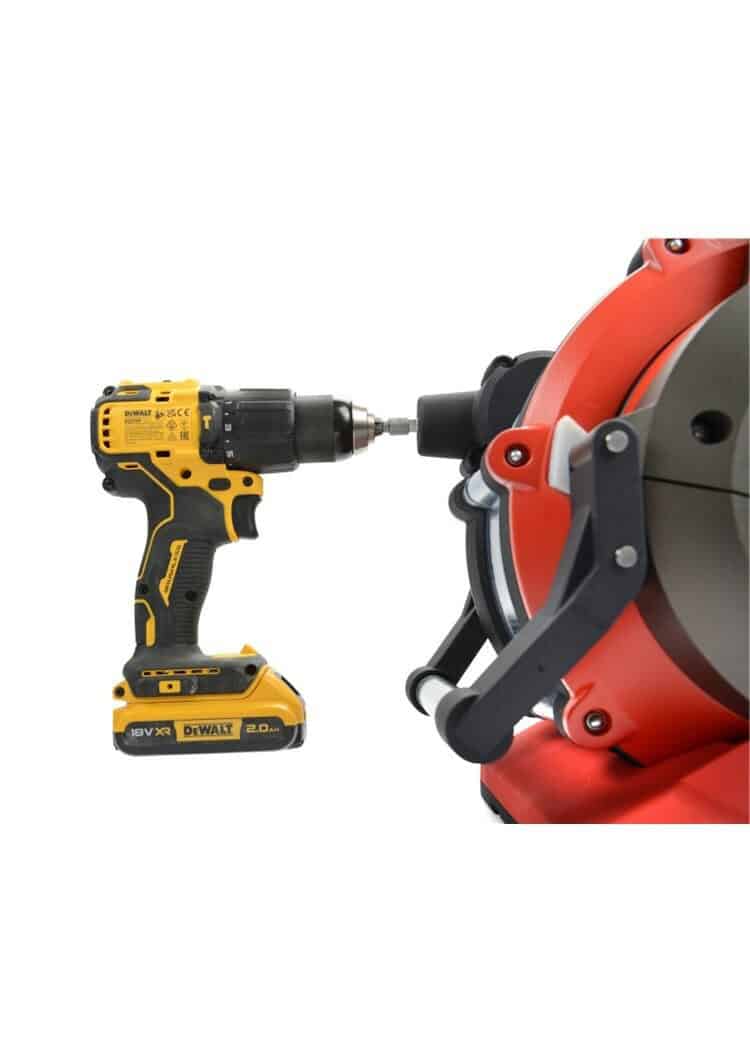

Following an initial concept exploration, we determined that the best route to developing an improved, faster and safer pipe cutting process, was to keep the pipe fixed and rotate our cutting mechanism around the pipe. We identified some key challenges and separated each of them into individual rigs: clamping, rotation of the cutting blade around a pipe and moving the cutting blade radially inward towards the pipe. These individual rigs could be combined onto a single frame. The learning on this was huge. We knew the forces involved would be considerable, but it became apparent just how critical this would be to the overall design. We developed the direction further and produced a new working prototype. It was this prototype that proved the concept and allowed us to proceed to engineering phases prior to Alpha/Pre-Pilot Prototypes. Engineering design is now nearly complete, and we are actively engaging heavily with suppliers before opening tooling.

The result

We are delighted that ProCut has been successfully launched by Drainfast at the tradeshow Plantworx 2023. The client has been using this to evaluate the market further and generate some presales interest prior to iterative changes and tooling. We collectively feel that it is a great product that fits well alongside other professional trade tools. The cutting process is efficient and the overall fatigue on workers is reduced. The tool significantly improves pipe cutting safety over some other pipe cutting methods.

ProCut

Faster Pipe Cutting

The brief

The relationship between Drainfast and Bang Creations continues to develop. The next challenge they shared with us, one that many of their clients have. How could the pipe cutting process for underground drainage pipes be improved? Specifically they wanted to improve the cut and chamfer process on 110mm diameter underground drainage pipes. The approaches commonly used on site are either slow or inherently dangerous, so much so that many sites prohibit cutting pipes with grinders. The developed pipe cutting tool would accompany the SiteStak, and also work well as a standalone tool. Bang previously developed a low-cost option for a cutting guide for their SiteStak’s, but Drainfast wanted to take this success further.

The bang

Following an initial concept exploration, we determined that the best route to developing an improved, faster and safer pipe cutting process, was to keep the pipe fixed and rotate our cutting mechanism around the pipe. We identified some key challenges and separated each of them into individual rigs: clamping, rotation of the cutting blade around a pipe and moving the cutting blade radially inward towards the pipe. These individual rigs could be combined onto a single frame. The learning on this was huge. We knew the forces involved would be considerable, but it became apparent just how critical this would be to the overall design. We developed the direction further and produced a new working prototype. It was this prototype that proved the concept and allowed us to proceed to engineering phases prior to Alpha/Pre-Pilot Prototypes. Engineering design is now nearly complete, and we are actively engaging heavily with suppliers before opening tooling.

The result

We are delighted that ProCut has been successfully launched by Drainfast at the tradeshow Plantworx 2023. The client has been using this to evaluate the market further and generate some presales interest prior to iterative changes and tooling. We collectively feel that it is a great product that fits well alongside other professional trade tools. The cutting process is efficient and the overall fatigue on workers is reduced. The tool significantly improves pipe cutting safety over some other pipe cutting methods.

ProCut

Faster Pipe Cutting

The brief

The relationship between Drainfast and Bang Creations continues to develop. The next challenge they shared with us, one that many of their clients have. How could the pipe cutting process for underground drainage pipes be improved? Specifically they wanted to improve the cut and chamfer process on 110mm diameter underground drainage pipes. The approaches commonly used on site are either slow or inherently dangerous, so much so that many sites prohibit cutting pipes with grinders. The developed pipe cutting tool would accompany the SiteStak, and also work well as a standalone tool. Bang previously developed a low-cost option for a cutting guide for their SiteStak’s, but Drainfast wanted to take this success further.

The bang

Following an initial concept exploration, we determined that the best route to developing an improved, faster and safer pipe cutting process, was to keep the pipe fixed and rotate our cutting mechanism around the pipe. We identified some key challenges and separated each of them into individual rigs: clamping, rotation of the cutting blade around a pipe and moving the cutting blade radially inward towards the pipe. These individual rigs could be combined onto a single frame. The learning on this was huge. We knew the forces involved would be considerable, but it became apparent just how critical this would be to the overall design. We developed the direction further and produced a new working prototype. It was this prototype that proved the concept and allowed us to proceed to engineering phases prior to Alpha/Pre-Pilot Prototypes. Engineering design is now nearly complete, and we are actively engaging heavily with suppliers before opening tooling.

The result

We are delighted that ProCut has been successfully launched by Drainfast at the tradeshow Plantworx 2023. The client has been using this to evaluate the market further and generate some presales interest prior to iterative changes and tooling. We collectively feel that it is a great product that fits well alongside other professional trade tools. The cutting process is efficient and the overall fatigue on workers is reduced. The tool significantly improves pipe cutting safety over some other pipe cutting methods.