LeShuffler:

Automatic Card Dealer

The brief

Sometimes you meet entrepreneurs who have a clear vision, relentless drive, and the knowledge to truly move a project forward. The LeShuffler project, conceived by François Steiner, was one of those. François had already validated the concept, collaborated with potential manufacturers to learn the key challenges, and even taught himself to code.

LeShuffler is a card-shuffling machine that loads, shuffles, and deals playing cards. It's perfect for families or serious card players alike, eliminating disputes over unfair shuffling and arguments about who’s next in line to shuffle.

Initially our brief was to mentor him through the process of bringing this idea to market. However Francois wanted a stand-out design so later we were asked to take the groundwork François had already done and mechanically engineer a working prototype to showcase the product. The goal? To help secure funding for the remaining development costs and bring this brilliant idea to life.

The bang

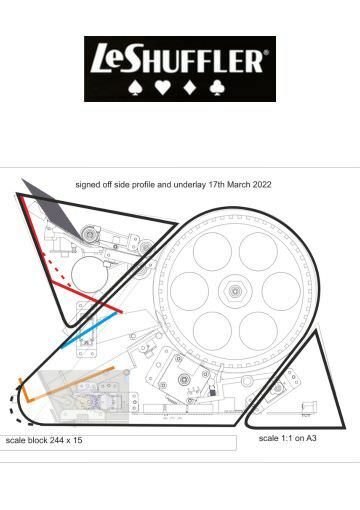

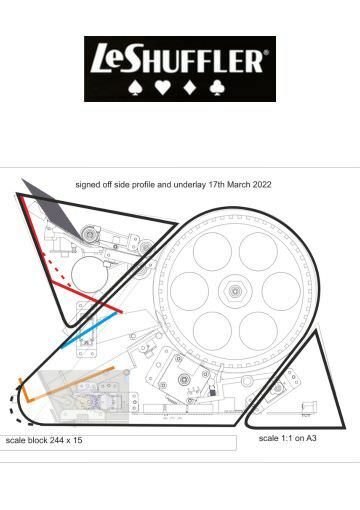

Our objective was to make this a wonderful product to have on your table. Make the product a talking point, something to be admired. We followed the journey of cards going in at the top, get shuffled at the back, and dealt on the playing surface.

We used our design model – “The Design Compass” to ensure our concept was as environmentally and socially responsible as possible. We focused on the styling and ability for it to be completely disassembled so each part could be accessed, repaired or replaced by the owner, making the product easy to maintain and be in use in the market for longer.

The primary mechanical engineering challenge we encountered was working with the fine tolerances of a single playing card and ensuring that the cards could seamlessly pass between mechanisms without jamming. We used 3D CAD, and VR to design and engineer the whole assembly, ensuring form, fit and function.

We removed most of the plastic parts are replaced them in metal making the product more robust and easier to recycle at end of life.

There is a significant number of moving parts, some of which are extremely small, so we needed to ensure that each component remained both robust and precise and can be made and Quality Controlled in production.

With this in mind we worked with several potential manufacturers globally, and as part of our drive to ensure every product we develop has minimal negative impact on people and planet as possible, we managed to create a design that can be manufactured commercially in France, significantly reducing the energy in production and distribution.

The result

The result is a sleek, stylish card-shuffling machine made from sustainable materials that fits seamlessly into any setting. The working prototype shuffles and deals cards efficiently and quickly, delivering a smooth user experience. With its thoughtful design and eco-friendly construction, it's as functional as it is visually appealing.

The Kickstarter campaign is now live and performing exceptionally well, having already exceeded its initial funding goal, and being on the Kickstarter’s “Products We Love List”. This success is a testament to the strong interest and belief in the product's potential, as well as Francois’s determination, attention to detail and drive – not to mention the skill sets in engineering and electronics he has picked up during the products development.

We're excited for the next steps, as we move towards scaling production and bringing this innovative device to market. The journey is just beginning, and we're eager to see where it leads!

LeShuffler:

Automatic Card Dealer

The brief

Sometimes you meet entrepreneurs who have a clear vision, relentless drive, and the knowledge to truly move a project forward. The LeShuffler project, conceived by François Steiner, was one of those. François had already validated the concept, collaborated with potential manufacturers to learn the key challenges, and even taught himself to code.

LeShuffler is a card-shuffling machine that loads, shuffles, and deals playing cards. It's perfect for families or serious card players alike, eliminating disputes over unfair shuffling and arguments about who’s next in line to shuffle.

Initially our brief was to mentor him through the process of bringing this idea to market. However Francois wanted a stand-out design so later we were asked to take the groundwork François had already done and mechanically engineer a working prototype to showcase the product. The goal? To help secure funding for the remaining development costs and bring this brilliant idea to life.

The bang

Our objective was to make this a wonderful product to have on your table. Make the product a talking point, something to be admired. We followed the journey of cards going in at the top, get shuffled at the back, and dealt on the playing surface.

We used our design model – “The Design Compass” to ensure our concept was as environmentally and socially responsible as possible. We focused on the styling and ability for it to be completely disassembled so each part could be accessed, repaired or replaced by the owner, making the product easy to maintain and be in use in the market for longer.

The primary mechanical engineering challenge we encountered was working with the fine tolerances of a single playing card and ensuring that the cards could seamlessly pass between mechanisms without jamming. We used 3D CAD, and VR to design and engineer the whole assembly, ensuring form, fit and function.

We removed most of the plastic parts are replaced them in metal making the product more robust and easier to recycle at end of life.

There is a significant number of moving parts, some of which are extremely small, so we needed to ensure that each component remained both robust and precise and can be made and Quality Controlled in production.

With this in mind we worked with several potential manufacturers globally, and as part of our drive to ensure every product we develop has minimal negative impact on people and planet as possible, we managed to create a design that can be manufactured commercially in France, significantly reducing the energy in production and distribution.

The result

The result is a sleek, stylish card-shuffling machine made from sustainable materials that fits seamlessly into any setting. The working prototype shuffles and deals cards efficiently and quickly, delivering a smooth user experience. With its thoughtful design and eco-friendly construction, it's as functional as it is visually appealing.

The Kickstarter campaign is now live and performing exceptionally well, having already exceeded its initial funding goal, and being on the Kickstarter’s “Products We Love List”. This success is a testament to the strong interest and belief in the product's potential, as well as Francois’s determination, attention to detail and drive – not to mention the skill sets in engineering and electronics he has picked up during the products development.

We're excited for the next steps, as we move towards scaling production and bringing this innovative device to market. The journey is just beginning, and we're eager to see where it leads!

LeShuffler:

Automatic Card Dealer

The brief

Sometimes you meet entrepreneurs who have a clear vision, relentless drive, and the knowledge to truly move a project forward. The LeShuffler project, conceived by François Steiner, was one of those. François had already validated the concept, collaborated with potential manufacturers to learn the key challenges, and even taught himself to code.

LeShuffler is a card-shuffling machine that loads, shuffles, and deals playing cards. It's perfect for families or serious card players alike, eliminating disputes over unfair shuffling and arguments about who’s next in line to shuffle.

Initially our brief was to mentor him through the process of bringing this idea to market. However Francois wanted a stand-out design so later we were asked to take the groundwork François had already done and mechanically engineer a working prototype to showcase the product. The goal? To help secure funding for the remaining development costs and bring this brilliant idea to life.

The bang

Our objective was to make this a wonderful product to have on your table. Make the product a talking point, something to be admired. We followed the journey of cards going in at the top, get shuffled at the back, and dealt on the playing surface.

We used our design model – “The Design Compass” to ensure our concept was as environmentally and socially responsible as possible. We focused on the styling and ability for it to be completely disassembled so each part could be accessed, repaired or replaced by the owner, making the product easy to maintain and be in use in the market for longer.

The primary mechanical engineering challenge we encountered was working with the fine tolerances of a single playing card and ensuring that the cards could seamlessly pass between mechanisms without jamming. We used 3D CAD, and VR to design and engineer the whole assembly, ensuring form, fit and function.

We removed most of the plastic parts are replaced them in metal making the product more robust and easier to recycle at end of life.

There is a significant number of moving parts, some of which are extremely small, so we needed to ensure that each component remained both robust and precise and can be made and Quality Controlled in production.

With this in mind we worked with several potential manufacturers globally, and as part of our drive to ensure every product we develop has minimal negative impact on people and planet as possible, we managed to create a design that can be manufactured commercially in France, significantly reducing the energy in production and distribution.

The result

The result is a sleek, stylish card-shuffling machine made from sustainable materials that fits seamlessly into any setting. The working prototype shuffles and deals cards efficiently and quickly, delivering a smooth user experience. With its thoughtful design and eco-friendly construction, it's as functional as it is visually appealing.

The Kickstarter campaign is now live and performing exceptionally well, having already exceeded its initial funding goal, and being on the Kickstarter’s “Products We Love List”. This success is a testament to the strong interest and belief in the product's potential, as well as Francois’s determination, attention to detail and drive – not to mention the skill sets in engineering and electronics he has picked up during the products development.

We're excited for the next steps, as we move towards scaling production and bringing this innovative device to market. The journey is just beginning, and we're eager to see where it leads!