Prototyping a consumer product

At Bang Creations, we utilise over 20-years’ experience in developing consumer and retail products to take to market. From toys, to household products, hair and beauty to furniture, we have a firm understanding of what it takes to design for manufacture and production.

We believe that the key to our success has been our understanding of how much it costs to design and manufacture a new product - the cost matrix. See evaluate.

When we are engaged in the product design process, we start by creating low fidelity product prototypes. These are a vital and inexpensive way to quickly share our design thinking process.

What is the target cost of a new product?

Designing innovative products for manufacture is what we do every day. The real challenge for us as product designers is in designing and making a product to a target cost (typically 20% of RRP). Consumer products have a complicated route to market, especially when selling products internationally via distributors.

If you want to know how to save money on product development costs, then we can help. The design must provide a margin to all involved in the chain that takes your product from manufacture to market.

To save funds on product development costs, we make several mock-up prototypes to test specific functions. These are tested, refined and then costed with our product manufacturing partners.

Our early prototypes

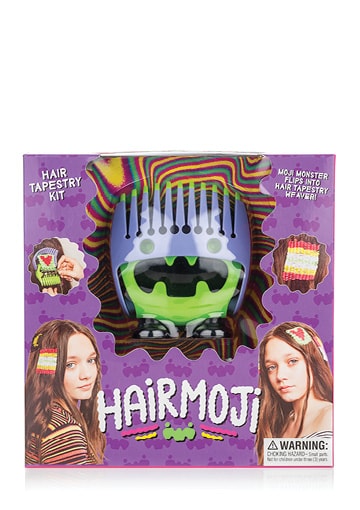

The Hairmoji product started off as an idea from our client, Bleach London. They came to us with a rough rig of a loom which proved their concept worked. They had trialled it at Glastonbury Festival and it was featured in magazines such as Vogue. They asked us to turn the concept into a consumer product.

Another of our projects, the Fluxuator, required us to make several prototypes. The first were made in blocks of wood and squeezy bottes. It was these early prototypes that proved the concept and the functionality.

Our solution

We are a product design and development agency that works with manufacturers from the concept stage onward. This development process delivers a better commercial product for our clients. Together, we deliver a Works Like, Looks Like (WLLL) prototype. This is a prototype that looks like the final product but is not representative of the Design for Manufacture (DfM).

This prototype helps us to answer crucial questions such as: How will people use my product? How can my product be simplified? How can I reduce manufacturing costs for my new product? How will customers understand my product’s function? Once we are satisfied, we can engineer product components for production.

The Works Like, Looks Like prototype

Once the Works Like, Looks Like (WLLL) prototype is signed off, the production engineering teams pour over every product component. At this stage, our product design team often take the design of your new product into Virtual Reality (VR) to assess assembly challenges and changes to tooling, assembly time and product cost. These product components are then 3D printed or CNC to make the Pre-Production Prototype (PPP).

Where possible, we endeavour to make the Works Like, Looks Like (WLLL) prototype as close to the manufacture product as we can.

The prototype

The purpose of this WLLL prototype is to market test the design. How is it used? Does the customer understand what the product does just by looking at it? Is there anything we can learn from testing it to make the design simpler? Therefore, they are often made prior to engineering each component for production.

Hairmoji: The concept and detail design stages delivered a fun, funky solution for the Hairmoji concept. We made a character that the clients called – Hairmoji. We strove to make the products with as few parts as possible because we knew that the top RRP of the product would be £14.99 or in mass batch production could go as low as £9.99 and $9.99 in the US. We therefore 3d printed several forms to check the function first.

The outcome

Once the WLLL is signed off, the production engineering teams pour over every component to make sure that they are designed as efficiently as possible. We often take the design into VR to check for assembly challenges and see if anything can be simplified to save tooling costs, assembly time and product cost. These individual parts are then 3D printed or CNC and combined to make the Pre-Production Prototype. (PPP).

Prototyping a consumer product

At Bang Creations, we utilise over 20-years’ experience in developing consumer and retail products to take to market. From toys, to household products, hair and beauty to furniture, we have a firm understanding of what it takes to design for manufacture and production.

We believe that the key to our success has been our understanding of how much it costs to design and manufacture a new product – the cost matrix. See evaluate.

When we are engaged in the product design process, we start by creating low fidelity product prototypes. These are a vital and inexpensive way to quickly share our design thinking process.

What is the target cost of a new product?

Designing innovative products for manufacture is what we do every day. The real challenge for us as product designers is in designing and making a product to a target cost (typically 20% of RRP). Consumer products have a complicated route to market, especially when selling products internationally via distributors.

If you want to know how to save money on product development costs, then we can help. The design must provide a margin to all involved in the chain that takes your product from manufacture to market.

To save funds on product development costs, we make several mock-up prototypes to test specific functions. These are tested, refined and then costed with our product manufacturing partners.

Our early prototypes

The Hairmoji product started off as an idea from our client, Bleach London. They came to us with a rough rig of a loom which proved their concept worked. They had trialled it at Glastonbury Festival and it was featured in magazines such as Vogue. They asked us to turn the concept into a consumer product.

Another of our projects, the Fluxuator, required us to make several prototypes. The first were made in blocks of wood and squeezy bottes. It was these early prototypes that proved the concept and the functionality.

Our solution

We are a product design and development agency that works with manufacturers from the concept stage onward. This development process delivers a better commercial product for our clients. Together, we deliver a Works Like, Looks Like (WLLL) prototype. This is a prototype that looks like the final product but is not representative of the Design for Manufacture (DfM).

This prototype helps us to answer crucial questions such as: How will people use my product? How can my product be simplified? How can I reduce manufacturing costs for my new product? How will customers understand my product’s function? Once we are satisfied, we can engineer product components for production.

The Works Like, Looks Like prototype

Once the Works Like, Looks Like (WLLL) prototype is signed off, the production engineering teams pour over every product component. At this stage, our product design team often take the design of your new product into Virtual Reality (VR) to assess assembly challenges and changes to tooling, assembly time and product cost. These product components are then 3D printed or CNC to make the Pre-Production Prototype (PPP).

Where possible, we endeavour to make the Works Like, Looks Like (WLLL) prototype as close to the manufacture product as we can.

The prototype

The purpose of this WLLL prototype is to market test the design. How is it used? Does the customer understand what the product does just by looking at it? Is there anything we can learn from testing it to make the design simpler? Therefore, they are often made prior to engineering each component for production.

Hairmoji: The concept and detail design stages delivered a fun, funky solution for the Hairmoji concept. We made a character that the clients called – Hairmoji. We strove to make the products with as few parts as possible because we knew that the top RRP of the product would be £14.99 or in mass batch production could go as low as £9.99 and $9.99 in the US. We therefore 3d printed several forms to check the function first.

The outcome

Once the WLLL is signed off, the production engineering teams pour over every component to make sure that they are designed as efficiently as possible. We often take the design into VR to check for assembly challenges and see if anything can be simplified to save tooling costs, assembly time and product cost. These individual parts are then 3D printed or CNC and combined to make the Pre-Production Prototype. (PPP).

Prototyping a consumer product

At Bang Creations, we utilise over 20-years’ experience in developing consumer and retail products to take to market. From toys, to household products, hair and beauty to furniture, we have a firm understanding of what it takes to design for manufacture and production.

We believe that the key to our success has been our understanding of how much it costs to design and manufacture a new product – the cost matrix. See evaluate.

When we are engaged in the product design process, we start by creating low fidelity product prototypes. These are a vital and inexpensive way to quickly share our design thinking process.

What is the target cost of a new product?

Designing innovative products for manufacture is what we do every day. The real challenge for us as product designers is in designing and making a product to a target cost (typically 20% of RRP). Consumer products have a complicated route to market, especially when selling products internationally via distributors.

If you want to know how to save money on product development costs, then we can help. The design must provide a margin to all involved in the chain that takes your product from manufacture to market.

To save funds on product development costs, we make several mock-up prototypes to test specific functions. These are tested, refined and then costed with our product manufacturing partners.

Our early prototypes

The Hairmoji product started off as an idea from our client, Bleach London. They came to us with a rough rig of a loom which proved their concept worked. They had trialled it at Glastonbury Festival and it was featured in magazines such as Vogue. They asked us to turn the concept into a consumer product.

Another of our projects, the Fluxuator, required us to make several prototypes. The first were made in blocks of wood and squeezy bottes. It was these early prototypes that proved the concept and the functionality.

Our solution

We are a product design and development agency that works with manufacturers from the concept stage onward. This development process delivers a better commercial product for our clients. Together, we deliver a Works Like, Looks Like (WLLL) prototype. This is a prototype that looks like the final product but is not representative of the Design for Manufacture (DfM).

This prototype helps us to answer crucial questions such as: How will people use my product? How can my product be simplified? How can I reduce manufacturing costs for my new product? How will customers understand my product’s function? Once we are satisfied, we can engineer product components for production.

The Works Like, Looks Like prototype

Once the Works Like, Looks Like (WLLL) prototype is signed off, the production engineering teams pour over every product component. At this stage, our product design team often take the design of your new product into Virtual Reality (VR) to assess assembly challenges and changes to tooling, assembly time and product cost. These product components are then 3D printed or CNC to make the Pre-Production Prototype (PPP).

Where possible, we endeavour to make the Works Like, Looks Like (WLLL) prototype as close to the manufacture product as we can.

The prototype

The purpose of this WLLL prototype is to market test the design. How is it used? Does the customer understand what the product does just by looking at it? Is there anything we can learn from testing it to make the design simpler? Therefore, they are often made prior to engineering each component for production.

Hairmoji: The concept and detail design stages delivered a fun, funky solution for the Hairmoji concept. We made a character that the clients called – Hairmoji. We strove to make the products with as few parts as possible because we knew that the top RRP of the product would be £14.99 or in mass batch production could go as low as £9.99 and $9.99 in the US. We therefore 3d printed several forms to check the function first.

The outcome

Once the WLLL is signed off, the production engineering teams pour over every component to make sure that they are designed as efficiently as possible. We often take the design into VR to check for assembly challenges and see if anything can be simplified to save tooling costs, assembly time and product cost. These individual parts are then 3D printed or CNC and combined to make the Pre-Production Prototype. (PPP).