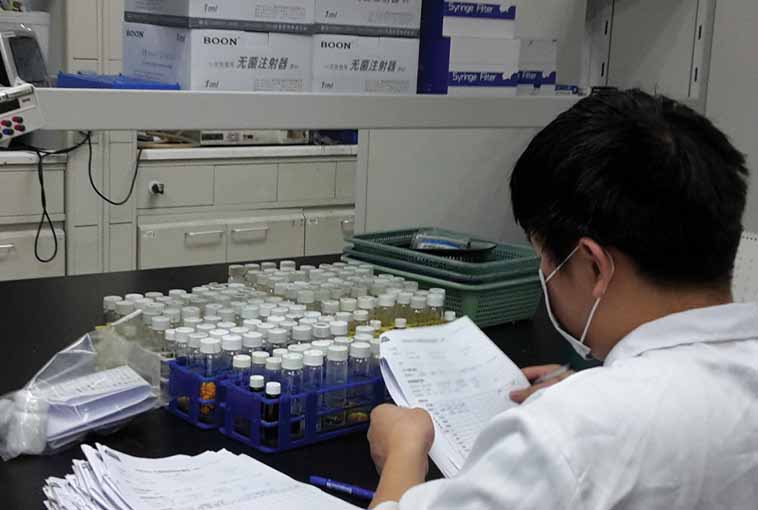

Safety Testing: Product safety design & testing

Anticipating safety

With the works like looks like prototype, or prototype test rigs we are often able to ask one of the test houses for a review. It has often proven invaluable for an early stage review, prior to submitting pre-production prototypes. This is essential to the product design development process, so as we can progress onto the engineering stage aware of safety concerns.

Testing to national & international standards

We work with many test houses both here in the UK and in Asia alongside our manufacturing partners. During the product evaluation stage, we identify which standards the product needs to pass. As members of the British Standards Institute and having worked on a variety of different products we have easy access to the relevant standards.

During the concept and detail design stages we work to the standards as much as we can and when we have a prototype, ideally the works like looks like or some test rigs, we then send them off for a safety review.

Critical safety directives

The safety review identifies the standards to which the product would be tested and also undertakes a general safety directive. As we are often innovating new product, the concept falls between two or more test standards, and they will identify what is a potential “critical, major or minor” concern.

Concern levels

A critical concern is one that can cause death or life changing injury, a major concern is one that can cause serious injury and minor concerns are ones that can cause minor injuries. A finger pinch for example would be classed as a minor, but a chopped finger would be a major concern. The safety review not only helps us identify the safety risks so as we can design them out early as possible in the development process, but also identifies risks in production assembly, potential damage to parts and helps us identify what needs clear communication to the consumer either in the instructions or as labels that should be applied to the product at point of sale.

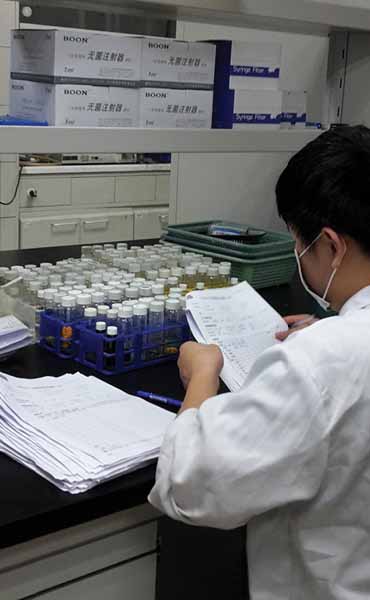

Safety Testing: Product safety design & testing

Anticipating safety

With the works like looks like prototype, or prototype test rigs we are often able to ask one of the test houses for a review. It has often proven invaluable for an early stage review, prior to submitting pre-production prototypes. This is essential to the product design development process, so as we can progress onto the engineering stage aware of safety concerns.

Testing to national & international standards

We work with many test houses both here in the UK and in Asia alongside our manufacturing partners. During the product evaluation stage, we identify which standards the product needs to pass. As members of the British Standards Institute and having worked on a variety of different products we have easy access to the relevant standards.

During the concept and detail design stages we work to the standards as much as we can and when we have a prototype, ideally the works like looks like or some test rigs, we then send them off for a safety review.

Critical safety directives

The safety review identifies the standards to which the product would be tested and also undertakes a general safety directive. As we are often innovating new product, the concept falls between two or more test standards, and they will identify what is a potential “critical, major or minor” concern.

Concern levels

A critical concern is one that can cause death or life changing injury, a major concern is one that can cause serious injury and minor concerns are ones that can cause minor injuries. A finger pinch for example would be classed as a minor, but a chopped finger would be a major concern. The safety review not only helps us identify the safety risks so as we can design them out early as possible in the development process, but also identifies risks in production assembly, potential damage to parts and helps us identify what needs clear communication to the consumer either in the instructions or as labels that should be applied to the product at point of sale.

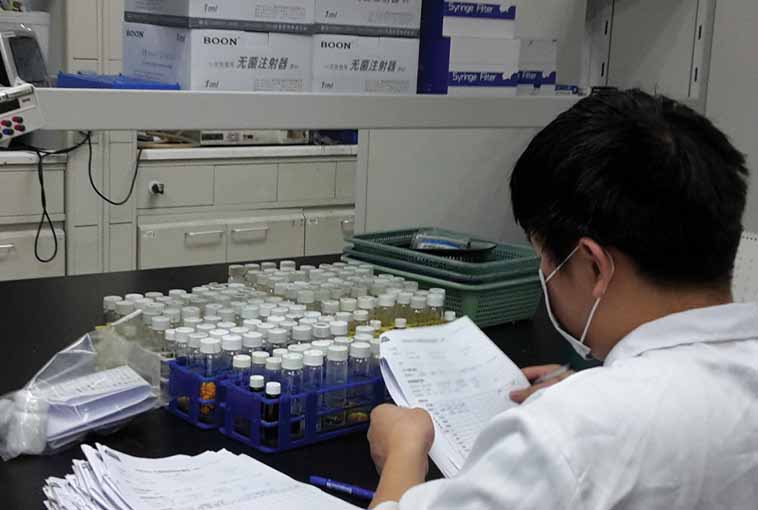

Safety Testing: Product safety design & testing

Anticipating safety

With the works like looks like prototype, or prototype test rigs we are often able to ask one of the test houses for a review. It has often proven invaluable for an early stage review, prior to submitting pre-production prototypes. This is essential to the product design development process, so as we can progress onto the engineering stage aware of safety concerns.

Testing to national & international standards

We work with many test houses both here in the UK and in Asia alongside our manufacturing partners. During the product evaluation stage, we identify which standards the product needs to pass. As members of the British Standards Institute and having worked on a variety of different products we have easy access to the relevant standards.

During the concept and detail design stages we work to the standards as much as we can and when we have a prototype, ideally the works like looks like or some test rigs, we then send them off for a safety review.

Critical safety directives

The safety review identifies the standards to which the product would be tested and also undertakes a general safety directive. As we are often innovating new product, the concept falls between two or more test standards, and they will identify what is a potential “critical, major or minor” concern.

Concern levels

A critical concern is one that can cause death or life changing injury, a major concern is one that can cause serious injury and minor concerns are ones that can cause minor injuries. A finger pinch for example would be classed as a minor, but a chopped finger would be a major concern. The safety review not only helps us identify the safety risks so as we can design them out early as possible in the development process, but also identifies risks in production assembly, potential damage to parts and helps us identify what needs clear communication to the consumer either in the instructions or as labels that should be applied to the product at point of sale.